At mid-year in 2021, supplies of raw materials, plastic resins such as polyethylene (PE), polypropylene (PP) and compounded plastics remained very tight. Prices hit historic highs in March 2021. Makers of plastic products watched their lead times grow and costs increase. Supply and demand imbalances caused delays in delivery or even production stoppages.

What Are Effects of the Plastics Shortage?

Two of the most widely produced types of thermoplastic polymer resins are polyethylene and polypropylene. Polyethylene (PE) is used for electrical insulation, medical equipment, packaging, films, tubes or laminates, among other products. Polypropylene (PP) is commonly used in plastic injection molding and is needed to produce durable plastic parts such as automobile bumpers, for example.

The lack of raw materials supply hit resin markets hard, not only in the United States, home to the world’s largest petrochemical processing plants. By April, shortages of polymer resin had affected 90% of European converters, according to the European Plastics Converters (EuPC) trade group. This has hurt some 50,000 small and medium-size companies that make materials and products for construction, packaging, electronics, and the automotive industries.

What Are Causes of the Plastics Shortage?

Similar to the semiconductor shortage, the plastics shortage of 2021 did not happen overnight. Rather, it was a series of seemingly unrelated events. And like the nine poisonous heads of a hydra, threats are coming at you from all directions. Sometimes all at once. Even if you manage to hack off one of the heads, another grows in its place. Contributors to the plastics shortage include:

Pandemic conditions – Early in the COVID-19 pandemic, plummeting oil prices and low demand led oil companies to cut production. During lockdowns, demand for plastic products and products containing plastic increased sharply. Yet quarantines restricted productivity at chemical and processing plants, so many polymer suppliers could not fulfill orders.

Maintenance delays – Polymer production facilities must be regularly shut down for extensive maintenance. Yet COVID-19 restrictions delayed most scheduled 2020 shutdowns, which must now be performed. And turnaround takes longer with pandemic health and safety restrictions, when fewer workers are on site.

A perfect storm – In mid-2020, extreme weather during the hurricane season in the US disrupted hydrocarbon extraction and processing. Then this past February, the severe winter storm Uri caused power outages and freeze damage to equipment and pipes in the US Gulf Coast, which crippled resin production.

Plant disasters – Major fire damage and leaks in major chemical processing plants occurred in locations including Louisiana, Germany, the United Kingdom and South Korea.

How Can an SCRM Solution Help You Deal with the Plastics Shortage?

By being risk aware, reacting fast, being proactive and with a reliable partner, businesses can outpace multiple threats and emerge victorious. Sphera Supply Chain Risk Management [formerly ris

kmethods] can be your secret advantage to get ahead of today’s plastics shortage risk. By connecting the dots on seemingly unrelated events, you are better prepared for adverse risk events. Through the power of artificial intelligence you can react faster to the risks in your supply chain.

Here’s how:

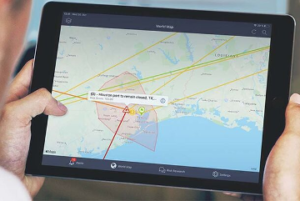

Supply chain visibility – Sphera Supply Chain Risk Management [formerly riskmethods] enables global visibility by mapping your

supply chains from customers to sub-tier. You can be aware of market trendsand emerging threats anywhere in the world.

Real-time information and early warning signs – Sphera Supply Chain Risk Management [formerly riskmethods] provides up-to-the-minute warnings for any of your plastics-related sites, suppliers, customers, locations, or countries. These include oil refineries, chemical companies, and leading plastics manufacturers.

The warnings also include alerts of extreme weather events and power outages affecting plastics and chemicals producers, among others. Real-time monitoring alerts customers to disaster at business partner sites, industrial disputes and force majeure. Sphera Supply Chain Risk Management [formerly riskmethods] can also send notices of site relocation or closure, and cuts or halts in resin production, including maintenance-related stoppage. Financial warnings include revenue and growth outlook. Beginning to recognize any patterns?

Impact analysis – Understand how critical threats are to your organization. For example, when you uncover single-source situations in advance, you have more time to develop alternatives.

Proactive risk mitigation tools – With the dashboard and advanced analytic tools provided by Sphera Supply Chain Risk Management [formerly riskmethods], you can streamline your activities. When you have action plans in place, everybody already knows what to do should a crisis strike.

Thanks to this increased risk awareness, you can be proactive about shortages and disruptions. You can react faster than your competitors to secure the remaining material and avoid rising market prices.

Building Resilient Supply Chains is Your Best Prevention

It’s the nature of the beast that manufacturers are vulnerable to shortages and supply chain disruptions. So, you need to understand where and when the next threat is about to strike. But how do you do this, and how do you do it quickly?

The first step is to map your tier-1 suppliers and logistics hubs. And to build more resilient supply chains, we recommend that you delve into your sub-tiers. By being risk aware, reacting faster and being proactive, you can stay ahead of risk.

riskmethods was acquired by Sphera in October 2022. This content originally appeared on the riskmethods website and was slightly modified for sphera.com.